Phased Array Ultrasonic Testing (PAUT)

is an advanced non-destructive examination technique that utilizer a set of ultrasonic testing(UT)

probes made up of numerous small elements, each of which is pulsed individually with computer-calculated timing.

This technique can be used to inspect more complex geometries that are difficult and much

slower to inspect with single probes. PAUT can be used to inspect almost any material

where traditional UT methods have been utilized, and is often used for weld inspections

and crack detection.

Compared to other forms of UT, PAUT has several advantages. PAUT can be conducted

more quickly. It has a high degree of repeatability. By emitting multiple angles sequentially,

PAUT is able to create detailed and accurate cross-sections of a part. It is also particularly

useful in situations where there is less room for mechanical scanning because it is able to

sweep the beam without moving the probe.

- Capacity to perform Carbon Steel Butt Weld Inspection

- Any joint configuration shall be inspected, such as pipe to pipe, pipe to flange, nozzle to pipe, etc.

- Diameter range from 0.85” inch to infinite diameter.

- Thickness ranges from 4 mm to 120 mm.

- High system sensitivity and less sensitive to false call

- High probability of deduction

- Capacity to perform Carbon Steel Butt and Stainless Flange.

- Any flange configuration shall be inspected, such as RTJ, Raised face, weld neck, etc

- Flange Diameter ranges from 1.0” inch to infinite diameter

- Thickness ranges from 10 mm to 120 mm.

- High system sensitivity and repeatability.

- Produce repeatable, reproducible and reliable result.

- Corrosion deduction on Carbon Steel above ground storage tank

- Any diameter shall be inspected.

- Thickness ranges from 6mm and above shall be inspected.

- Able to deduct the corrosion in broad severity level.

- Able to discriminate corrosion either on bottom or top of the plate.

- High sensitivity, good screening com sizing tool.

- High probability of deduction and less prone for false call.

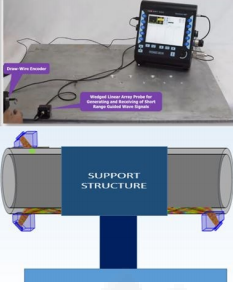

- SRUT - Short Range Ultrasonic Testing shall be used for detection of corrosion on under pipe support

- Guided Wave is a technique which uses low frequency sound waves to flood thin wall material and then reflect back at interfaces such as cracking or corrosion/ pitting.

- The guided wave technique is to be used as a screening tool and measure the remaining wall thickness as a propositae amplitude response.

- Limited access - insulated line with minimal insulation removal, corrosion under supports without need for lifting, inspection at elevated locations with minimal need for scaffolding, and inspection of road crossings and buried pipes. Data is fully recorded. Fully automated data collection protocols.

- Inspect Corrosion on carbon steel pipe, vessel and tank.

- Diameter from 4 inch and above shall be inspected by the use of Hydroform Scanner and Olympus search unit.

- Thickness ranges from 4 mm and above shall be inspected.

- Able to deduct the corrosion in both top and bottom of the scope.

- Capable to deduct 0.5 mm depth wall loss.

- High sensitivity, good screening com sizing tool.

- High probability of deduction ad less prone for false call.

Inquiry?

Send us an email or fill in the form if you have any inquiries