COMPUTED RADIOGRAPHY

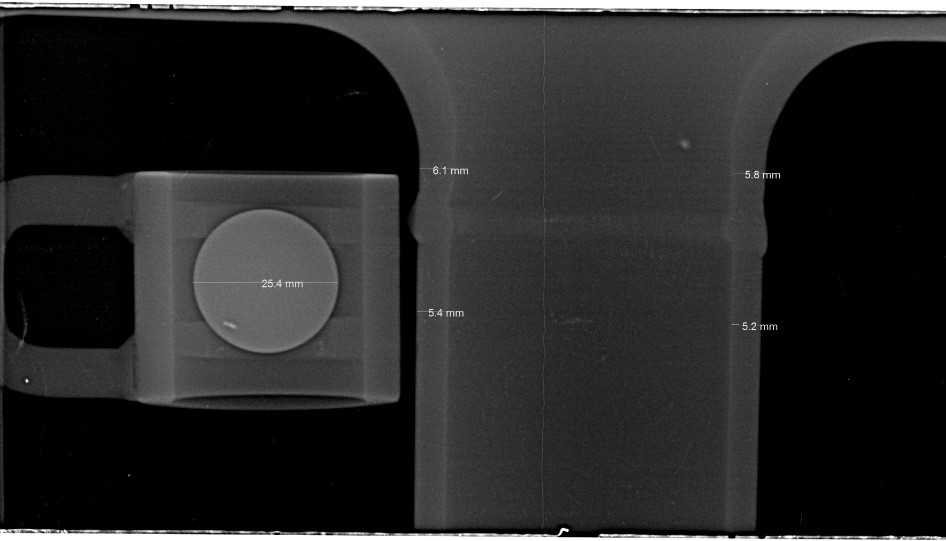

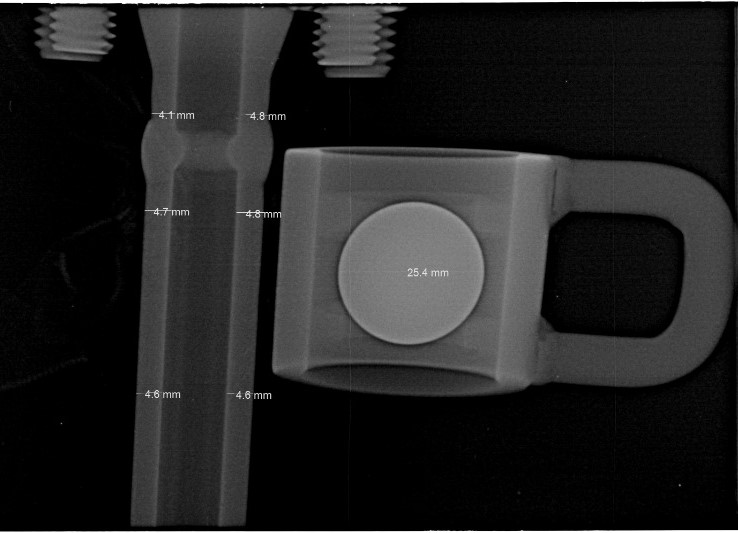

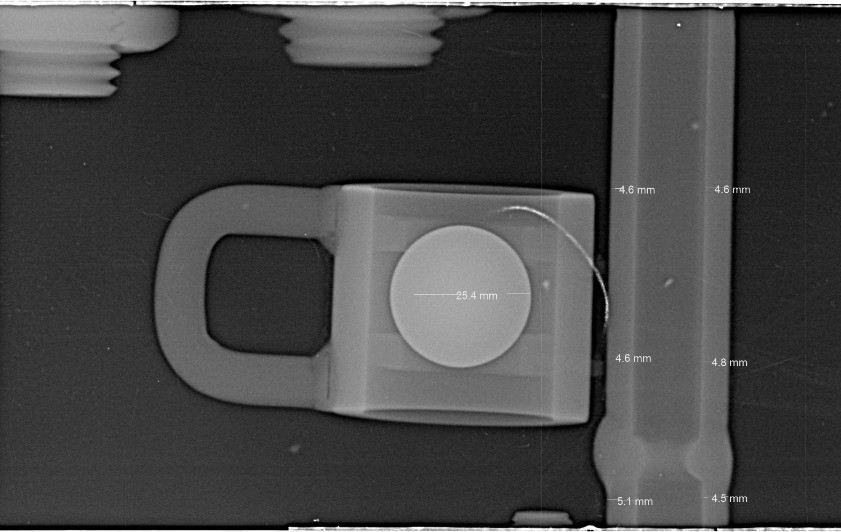

Computed Radiography (CR) is the digital replacement of convetional X-ray film radiography and offers enormous advantages for inspection tasks - the use of consumables is virtually eliminated ad the time to produce an image is drastically shortened.

- Image plates are reusable

- No darkroom or chemical needed

- Reduction in exposure and processing time

- Software-based evaluation and reporting

- Simple digital data exchange and archiving

HOW EXACTLY DOES CR TECHNOLOGY WORK? In computed radiography, when imaging plates are exposed to X-rays or gamma rays, the energy of the incoming radiation is stored in a special phosphor layer. A specialized machine known as a scanner is then used to read out the latent image from the plate by stimulating it with a very finely focused laser beam. When stimulated, the plate emits blue light with intensity proportional to the amount of radiation received during the exposure. The light is then detected by a highly sensitive analog device known as a photomultiplier (PMT) and converted to a digital signal using an analog-to-digital converter (ADC). The generated digital X-ray image can then be viewed on a computer monitor and evaluated. After an imaging plate is read, it is erased by a high intensity light source and can immediately be re-used - imaging plates can typically be used up to 1000 times or more depending on the application.

Inquiry?

Send us an email or fill in the form if you have any inquiries